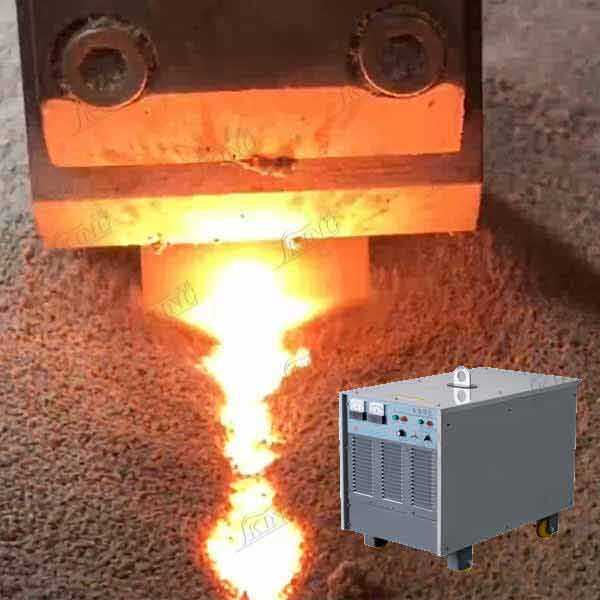

rolling mill stand esw

The rolling mill stand ESW represents a cutting-edge advancement in metal processing technology, designed to deliver superior precision and efficiency in metal forming operations. This sophisticated system combines robust mechanical engineering with advanced control systems to ensure optimal performance in various rolling applications. The stand features a state-of-the-art drive system that enables precise control over rolling parameters, including speed, pressure, and gap adjustment. Its innovative design incorporates enhanced stability mechanisms that significantly reduce vibration during operation, resulting in more consistent product quality. The ESW stand is equipped with advanced load monitoring systems that continuously analyze and adjust rolling forces to maintain optimal processing conditions. This technology is particularly valuable in producing flat products, such as sheets and plates, where dimensional accuracy is crucial. The system's modular construction allows for easy maintenance and upgrades, while its integrated cooling systems ensure consistent temperature control during operation. With capabilities to handle various metal types and thicknesses, the ESW stand has become an essential component in modern metal processing facilities, serving industries from automotive to construction materials production.