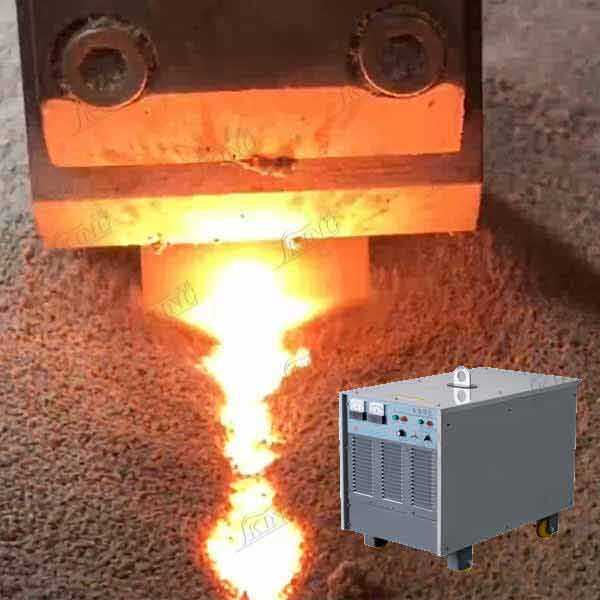

energy efficient esw machines

Energy efficient ESW (Electronic Switch-Mode) machines represent a significant advancement in industrial automation and manufacturing technology. These sophisticated devices are designed to optimize energy consumption while maintaining high performance levels across various applications. The machines incorporate advanced power management systems that automatically adjust power usage based on operational demands, resulting in substantial energy savings. They feature intelligent control mechanisms that monitor and regulate power consumption in real-time, utilizing advanced sensors and microprocessors to maintain optimal efficiency levels. The technology includes variable frequency drives, regenerative braking systems, and smart standby modes that significantly reduce energy waste during idle periods. These machines are equipped with high-efficiency motors and components that minimize power losses and heat generation. They also incorporate advanced insulation materials and thermal management systems to maintain optimal operating temperatures. The machines are particularly valuable in manufacturing processes, packaging operations, and industrial automation applications where continuous operation is required. Their adaptive power management capabilities make them ideal for facilities seeking to reduce their carbon footprint and operating costs while maintaining productivity standards. The integration of modern communication protocols allows these machines to be seamlessly incorporated into smart factory environments, enabling remote monitoring and predictive maintenance capabilities.