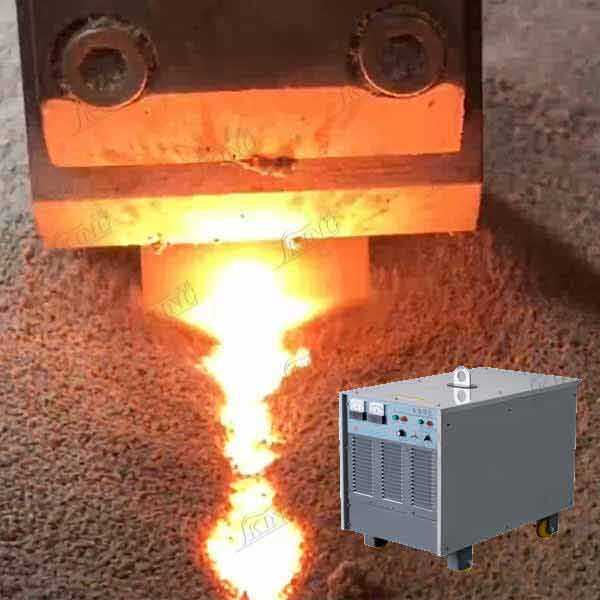

esw machine

The ESW machine represents a groundbreaking advancement in industrial processing technology, combining precision engineering with intelligent automation. This sophisticated system integrates multiple processing capabilities into a single unit, offering unprecedented versatility in manufacturing operations. At its core, the ESW machine utilizes advanced electromagnetic synchronization technology to achieve superior accuracy and consistency in material processing. The machine features a robust control system that enables real-time monitoring and adjustment of operational parameters, ensuring optimal performance across various applications. Its innovative design incorporates a modular architecture, allowing for easy customization and upgrades to meet specific production requirements. The ESW machine excels in high-precision cutting, forming, and assembly operations, making it particularly valuable in industries such as aerospace, automotive manufacturing, and precision engineering. The system's intelligent interface provides intuitive operation and comprehensive data analytics, enabling operators to maximize efficiency and maintain consistent quality standards. With its advanced safety features and ergonomic design, the ESW machine sets new standards in operational safety while maintaining exceptional productivity levels.