دليلك النهائي لآلات اللحام بالدرز الكهربائي

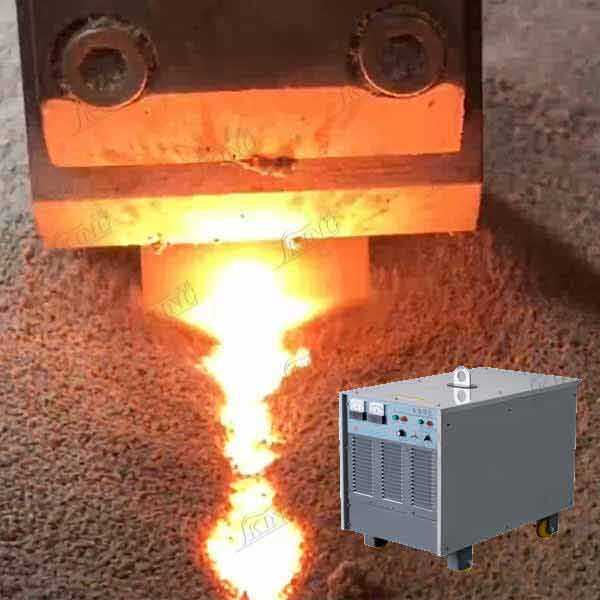

اكتشف قوة لحام المسامير بالقوس الكهربائي للتطبيقات الصناعية. تُعتبر هذه الطريقة أساسية لصناعات البناء والسيارات وبناء السفن، حيث تقدم قوة غير مسبوقة، وكفاءة تكلفة، وتنوعاً في المواد. تعرف على المبادئ الأساسية، الفوائد، وكيفية اختيار الجهاز المناسب.

عرض المزيد