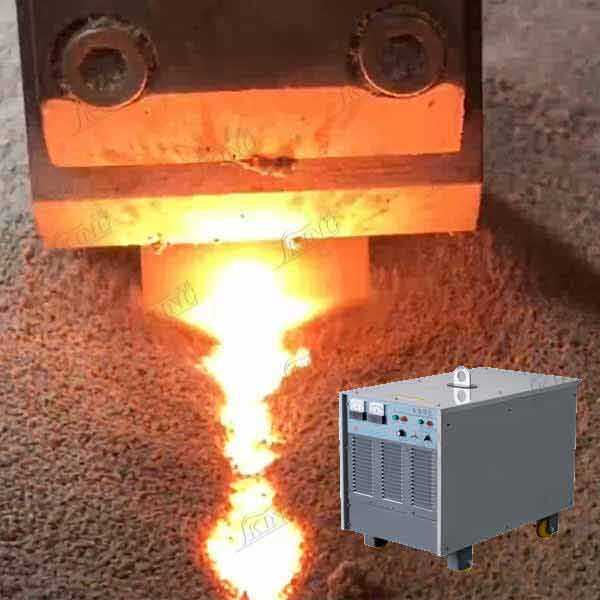

heavy duty esw welding

Heavy Duty Electroslag Welding (ESW) represents a sophisticated welding process specifically engineered for thick plate applications and large structural components. This advanced welding technique utilizes electrical resistance to generate heat, creating a molten slag bath that facilitates the joining of materials. The process stands out for its ability to complete deep penetration welds in a single pass, making it particularly efficient for materials ranging from 1 to 12 inches in thickness. The welding operation employs a consumable guide tube that feeds both the electrode wire and flux into the welding area, while water-cooled copper shoes contain the molten metal and slag. The process excels in vertical welding positions and is especially valuable in industries requiring high-integrity welds for thick sections. ESW delivers exceptional weld quality with minimal distortion, achieved through precise temperature control and uniform heat distribution. The technology incorporates advanced monitoring systems that ensure consistent weld parameters throughout the entire process, resulting in reliable and repeatable results. Its applications span across various sectors, including shipbuilding, heavy equipment manufacturing, structural steel fabrication, and power generation facilities, where robust and efficient welding solutions are essential for large-scale components.