Efficient suspended wire grade electroslag welding system

The Efficient Suspended Wire Grade Electroslag Welding System delivers high-speed, stable ESW welding for thick steel plates. This advanced electroslag welding equipment ensures superior weld quality, energy efficiency, and easy operation.

1. High Efficiency: One-pass electroslag welding up to 100mm.

2. Stable Power: IGBT inverter ensures consistent welds.

3. Cost Saving: Uses only welding wire as filler.

4. Easy Control: Automatic torch lifting system.

5. Safe & Reliable: Overload and cooling alarms.

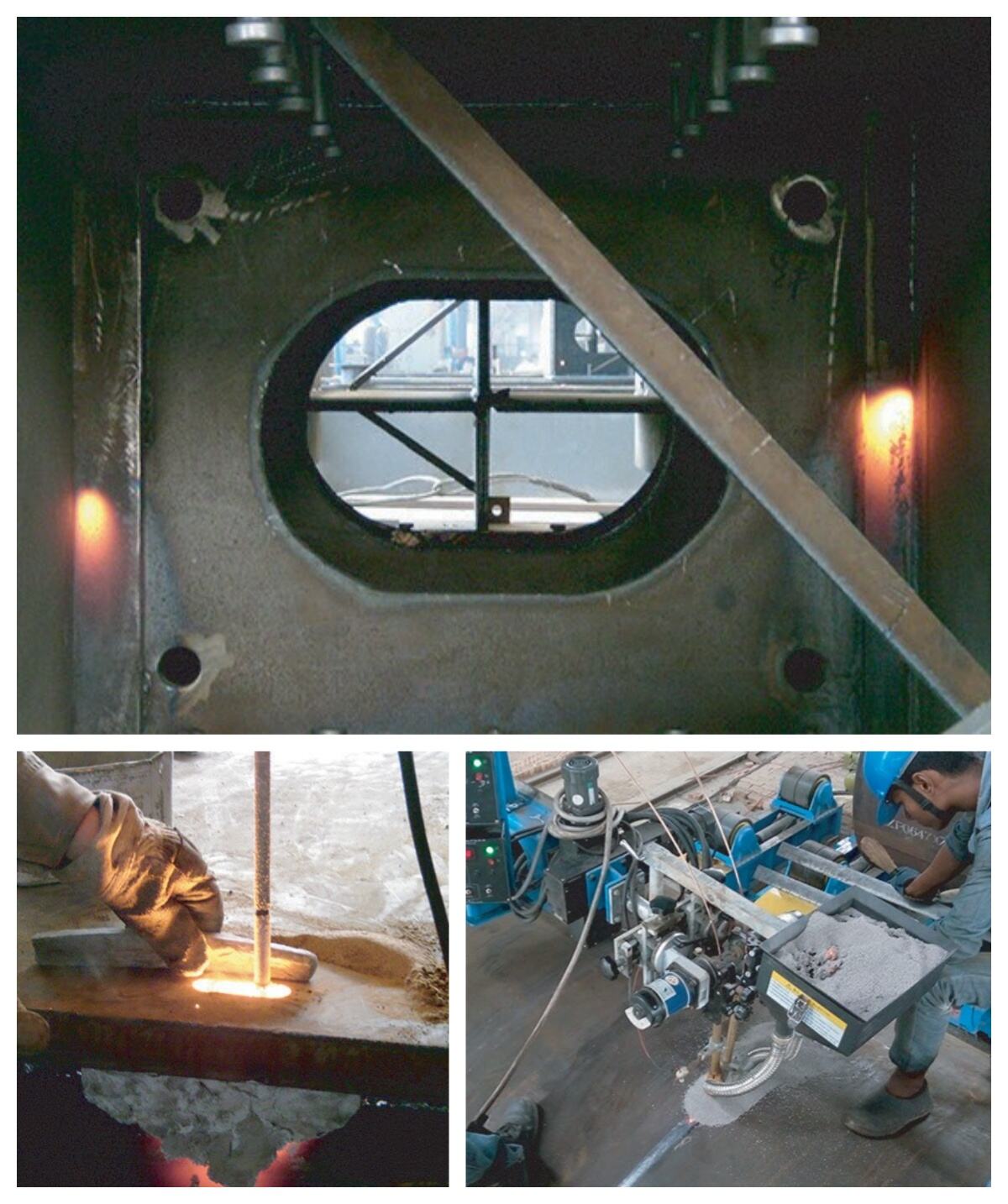

6. Wide Use: Ideal ESW welding system for box beams and columns.

- Overview

- Recommended Products

Place of Origin: |

CHINA |

Brand Name: |

IKING |

Certification: |

CQC |

Minimum Order Quantity: |

1 UNIT |

Packaging Details: |

Plywood Wooden Case |

Delivery Time: |

3-5 days |

Payment Terms: |

40%TT in advance, 60%Balance be baid before delivery |

Supply Ability: |

5 units/day |

Description:

Wire pole electroslag welding machine is an electroslag welding equipment that uses welding wire as electrode, and the wire is fed into the slag pool through the non-consumable electroslag welding gun and conductive nozzle. It is mainly used for efficient welding of vertical weld seams in steel structures, and is especially suitable for the welding of box-type columns and box-type beam bulkheads. It can weld very thick workpiece at one time, high welding speed, smooth welding process and not easy to produce spatter, with high melting rate.

Efficiency, high performance, stable and easy to operate

Specifications:

1. H7 Wire Electroslag Welding Power SourceSpecifications(IGBT)

Name |

Unit |

ZH7-1000 |

Weight |

KG |

95 |

Full Load Efficiency |

% |

89% |

No-load Voltage |

V |

120 |

Rated Welding Voltage |

V |

60 |

Rated Input Current |

A |

128 |

Full Load Power Factor |

- |

0.88 |

Rated Welding Current |

A |

1000 |

Voltage Output Range |

V |

22-60 |

Current Output Range |

A |

90-1000 |

Power Supply Rated Input Capacity |

KVA |

? |

Rated Load Duty Cycle |

% |

100 |

Welding Cable Cross-sectional Area |

mm² |

140 or 70×2 |

Three-phase Input Wire Cross-sectional Area |

mm |

16 |

User Air Switch Capacity |

A/V |

250/380 |

Power Input Voltage/Frequency |

V/Hz |

AV3X380/50 |

Overall Dimensions (L×W×H) |

mm |

823×371×840 |

2. Wire Feeder

Name |

Parameter |

Wire Feeding Motor Voltage |

24VDC |

Applicable Wire Reel |

Φ300×Φ50×103 |

Wire Feeding Speed Range |

1.5–15 m/min |

Wire Reel Capacity |

20kg |

Applicable Wire Diameter |

1.6mm |

Rated Traction Force |

15kg |

Volume |

9kg |

Overall Dimensions (L×W×H) |

460×200×280 mm |

3. Electroslag Welding Torch Lengths

Model |

Electroslag Welding Torch Length |

Applicable Weld Seam Length |

ZHS (L) |

1000mm |

720mm |

ZSN-10 |

1200mm |

920mm |

ZSN-12 |

1400mm |

1120mm |

ZSN-16 |

1600mm |

1320mm |

ZSN-18 |

1800mm |

1520mm |

ZSN-20 |

2000mm |

1720mm |

System Features

1. Using only welding wire as filler material reduces welding costs.

2. The use of fine welding wire and high current density results in a deposition rate of up to 140g/min, and the weld is formed in one pass, resulting in high welding efficiency.

3. The use of an oscillator allows single-wire welding of plates up to 100mm thick (compared to other manufacturers, which only have a plate thickness range of 16-65mm).

4. Easy to operate: The electroslag welding torch automatically raises according to the preset current, allowing a single operator to simultaneously operate two or more machines. 5. Extremely low equipment maintenance and repair costs. Utilizing cost-effective, highly reliable components readily available on the market, the system minimizes end-user costs.

6. The specially designed welding current detection and control system is independent of the ammeter pointer (unlike the Watanabe meter used by other welding manufacturers, which relies on the ammeter pointer), resulting in vibration resistance, high accuracy, and high reliability.

7. Features include slow wire feeding for arc ignition and arc termination with ball trimming (FTT) for more reliable arc ignition and eliminates the need to trim the wire end ball after welding.

8. Features include motor overload and short-circuit protection to prevent component damage from motor stalls and short circuits.

9. Features include three-axis (ZHS) or two-axis (ZHS(L)) position adjustment, horizontal rotation, cross-direction tilt adjustment, and wire cross alignment, enabling convenient adjustment of the electroslag welding gun position and angle to align the wire end with the welding gun axis.

10. Features include a trolley travel lock interface for connection to the trolley control system to prevent trolley movement during welding due to misoperation.

11. Features include a cooling water abnormality alarm. If the circulating cooling water tank is not open, or the cooling water flow is significantly reduced, interrupted, or blocked, an audible and visual alarm is issued to the user, automatically stopping the welding process to prevent damage to the welding gun and water-cooling cable from overheating.

Characteristics of electroslag welding power supply

ZH7 inverter slag welding machine is a high efficient and energy-saving DC power supply with IGBT inverter technology, which can weld carbon structural steel, low alloy structural steel, heat-resistant steel and its composite steel.

1、Small volume and light weight.

2、Wide range of current adjustment.

3、The use of IGBT inverter technology to ensure that the welding specifications in the grid voltage and load changes in a highly stable.

4、With protection function, when over temperature or grid voltage is too low to protect, at the same time the protection indicator light. With rectifier output abnormal alarm function.

5、Automatically stop the output if the arc is not established within 1min of starting.

6、High efficiency and power factor, thus it has significant power saving effect and high grid utilisation.

Wire Straightener Features and Parameters

The wire straightener consists of a cross straightener and an electroslag welding gun.

ZHS Special Electroslag Welding Gun

| Cooling System | Water |

| Rated Current | 500A |

| Duty Cycle | 100% |

| Electroslag Welding Gun Outer Diameter | Ø12 mm |

Cross Straightener

| Cross Straightener | Three-Point Roller, 2-Stage |

| Applicable Wire Diameter | Medium 1.6 mm |

Controller Features and Parameters

The controller contains the switches, knobs, and instruments required to operate the welding machine.

Instruments:

| Ammeter | 2.5 level, 600A, full scale |

| Welding voltmeter | 2.5 level, 100V, full scale |

| Wire feed voltmeter | 2.5 level, 30V, full scale |

Electroslag welding gun lift drive unit features and parameters

| Drive system | Rubber wheel friction drive |

| Lifting speed | 0-130mm/min |

| Drive motor | DC reduction motor |

| Electroslag welding gun angle adjustment | ±3 degrees in the cross direction (X and Y axes) |

Oscillator features and parameters

| Oscillating trajectory | Reciprocating linear motion |

| Oscillating amplitude | 0-100mm |

| Oscillating speed | 0-1600mm/min |

| Oscillating frequency at maximum amplitude | 0-8 times/min |

| Oscillating stop time | 0 or 1-12s (adjustable for left and right) |

| Weight | 9.4kg |

Applications:

1、Thickness of steel plate: 16-100mm

2、Steel type: low carbon steel, low alloy steel, medium carbon steel, refractory steel, etc.

3、Welding seam length: Maximum 1680mm (depends on the length of electroslag welding torch)

4、Welding seam structure: T-welding and butt-welding.