Efficient suspended double arc and double wire submerged arcwelding system (IGBT)

The Efficient Suspended Double Arc and Double Wire Submerged Arc Welding System (IGBT) delivers high-speed, stable twin arc welding with precise control and smooth seams. This advanced sub arc machine offers superior weld quality, energy efficiency, and reliability for heavy steel fabrication and automatic production lines.

1. Twin Arc, Double Speed: Dual-wire and double submerged arc welding boost efficiency and productivity.

2. IGBT Inverter Stability: Maintains consistent arc performance, smooth welds, and reduced spatter.

3. Suspended Structure: Flexible, easy to operate, and adjustable for different welding tasks.

4. Smart Control System: Preset current, voltage, and multiple welding modes for optimal precision.

5. Energy Efficient: Advanced inverter power supply saves energy and ensures long service life.

6. Compact Power Integration: Combines MZE-B, MZ-E, SQSS wire feeder, and MZK-C controller for reliable automated performance.

- Overview

- Recommended Products

| Place of Origin: | China |

| Brand Name: | IKING |

| Model Number: | IK-MZ1250-C1G |

| Minimum Order Quantity: | 1 unit |

| Packaging Details: | Sea worthy plywood box |

| Payment Terms: | 30% deposit to confirm order, balance to be paid before shipment against inspection |

Description:

This system adopts a suspended structure, which is more convenient to operate and can be adjusted according to actual needs.

The double-wire welding wire speeds up the welding speed, while the IGBT inverter technology ensures the stability of arc intensity and output power, greatly improving production efficiency.

Specifications:

1. MZE-B Submerged Arc Welding Power Supply

Item |

Unit |

MZE-1250B |

Rated Input Voltage |

V/Hz |

AC380V |

Frequency |

Hz |

50 |

Rated Input Current |

A |

118 |

Power Supply Capacity |

KVA |

78 |

No-load Voltage |

V |

88 |

Rated Welding Current |

A |

1250 |

Rated Welding Voltage |

V |

44 |

Rated Duty Cycle |

% |

60 |

Voltage Output Range |

V |

24~44 |

15~44 | ||

Current Output Range |

A |

100-1250 |

Full Load Efficiency |

% |

78 |

Full Load Power Factor |

|

0.83 |

User Air Switch Capacity |

A |

125A |

Three-phase Input Wire Cross-sectional Area |

mm² |

25 |

Welding Cable Cross-sectional Area |

mm² |

140 or 70×2 |

Dimensions (L×W×H) |

mm |

630×720×1417 |

Weight |

Kg |

210 |

2. MZ-E Series Submerged Arc Welding Power Supply (IGBT)

Item |

Unit |

MZ-1600E |

MZ-1250E |

Power Supply Input Voltage/Frequency |

V/Hz |

AC3X380/50 |

AC3X380/50 |

Grid |

KVA |

100 |

120 |

Minimum Power Supply Capacity |

KVA |

150 |

150 |

Generator |

KVA |

150 |

150 |

Rated Input Current |

A |

120 |

154 |

No-load Voltage |

|

78 |

78 |

Rated Welding Current |

A |

1250 |

1600 |

Rated Welding Voltage |

V |

44 |

44 |

Rated Duty Cycle |

% |

100 |

100 |

Voltage Output Range |

CC:23.6~44 |

CC:22.4~44 |

|

CV:22~44 |

CV:15~44 |

|

|

Current Output Range |

A |

90~1250 |

120~1600 |

Full Load Efficiency |

% |

89 |

89 |

Full Load Power Factor |

|

0.88 |

0.88 |

User Air Switch Capacity |

A/V |

160/380 |

200/380 |

Three-phase Input Wire Cross-sectional Area |

mm² |

25 |

35 |

Welding Cable Cross-sectional Area |

mm² |

140 or 70×2 |

140 or 70×2 |

Dimensions (L×W×H) |

mm |

823×371×840 |

944×583×1414.5 |

Weight |

Kg |

105 |

242 |

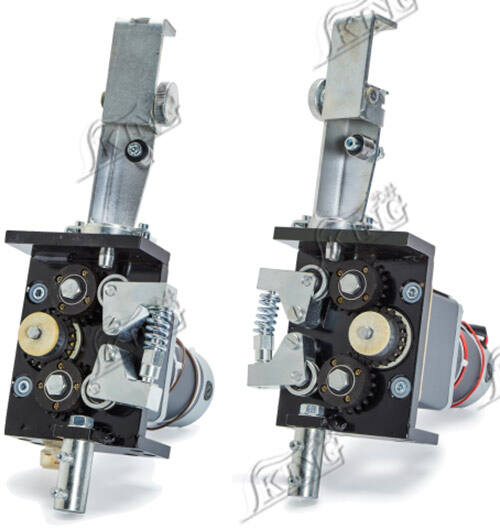

3. SQSS Wire Feeder

Item |

Parameter |

Power |

180W |

Rated Speed |

20 rpm |

Maximum Wire Feeding Speed |

3 m/min |

Wire Diameter Range |

Φ2.4~Φ6 mm |

Dimensions |

435×286.5×152 mm |

Mounting Dimensions |

110×25 hole distance |

Installation Holes |

4-M10 threaded holes |

Motor Rated Voltage |

110VDC |

Motor Maximum Current |

≤2.1 A |

4. MZK-C-1G Controller

Item |

Parameter |

Weight |

4.5 Kg |

Travel Motor |

100W |

Wire Feeding Motor |

200W |

Enclosure Protection Rating |

IP21 |

Maximum Operating Ambient Temperature |

45°C |

Wire Feeding Motor Excitation Voltage |

110VDC |

Travel Motor Voltage |

0~110VDC |

Wire Feeding Motor Voltage |

10~110VDC |

Input Power Supply |

120V ±20%, 50/60Hz |

Dimensions (W×D×H) |

305mm × 126mm × 242mm |

Features:

1. The advanced inverter power supply technology can quickly and stably control the current and voltage, thus achieving high-speed, efficient and high-quality welding.

2. This system is very flexible and can be used for different welding tasks, and can meet the requirements of complex welding tasks.

3. The double-wire submerged arc welding can weld two welds at the same time, improving production efficiency.

Ⅰ SQSS Wire Feeding Mechanism Features

The SQSS Dual Drive Wire Feeder is a dedicated wire feeder for submerged arc welding, suitable for feeding welding wires with diameters ranging from Φ2.4 to Φ6. It works in conjunction with the control box and submerged arc welding machine of the same manufacturer and can achieve automatic submerged arc welding on gantry or cantilever welding machines.

1. Uses a square box gear reducer.

2. Adopts dual wire feeding wheels, providing strong feeding force.

3. The motor and wire feeding mechanism are insulated, offering excellent electrical insulation performance.

4. The wire feeder can be installed in both left and right positions, making it adaptable to different installation positions.

Ⅱ Features of MZK-C-I

MKZ-C-I (G) submerged arc welding controller cooperates with MZ (MZE) submerged arc welding power supply and submerged arc welding carriage or head to realize automatic submerged arc welding. It is suitable for welding wires of different specifications and can weld carbon steel, low alloy steel, stainless steel, heat-resistant steel and its composite steel.

MKZ-C-I (DC) and MKZ-C-I (AC) cooperate with DC and AC submerged arc welding power supplies respectively to realize double arc double wire submerged arc welding.

1. Current, voltage and welding speed can be preset. 12 sets of welding process specifications can be stored.

2. When the wire is fed in an inching manner, the wire automatically stops feeding when it touches the workpiece to prevent bending of the wire and affecting arc initiation.

When the wire is bonded to the workpiece, the wire can be forced to feed.

3. It has the function of slow wire feeding and arc initiation.

4. It has the function of wire retraction when welding ends.

5. It automatically compensates for the grid voltage and arc fluctuations, and the welding process parameters are stable.

Ⅲ Features of MZ-E series arc welding power supply

MZ-E series inverter arc welding machine is an efficient and energy-saving arc welding equipment using IGBT inverter technology. It is suitable as a power source for arc welding, manual arc welding and gas shielded welding. It can weld carbon structural steel, low alloy structural steel, stainless steel, heat-resistant steel and its composite steel, etc. The rated welding current of the welding machine corresponds to the corresponding rated load duration. When the load duration increases, the maximum output current of the welding machine decreases accordingly. For example, when the load duration increases from 60% to 100%, the maximum output current is 0.7746 times the rated welding current.

1. Using IGBT inverter technology to ensure that the welding specification is highly stable when the grid voltage and arc length change.

2. High efficiency and power factor, thus having significant power saving effect and high grid utilization rate.

3. Wide current adjustment range, can be used for submerged arc welding and manual arc welding.

4. The welding current can be preset.

5. Suitable for fine wire and thick wire arc welding respectively.

6. Small size and light weight.

Ⅳ Features of MZE-B inverter arc welding machine

MZE-B series inverter submerged arc welding machine is an efficient and energy-saving arc welding equipment using IGBT inverter technology, suitable as a power source for arc welding, manual arc welding and gas shielded welding.

When using a single power supply, MZE-B AC square wave arc welding machine can perform single-wire arc welding, strip electrode cladding, narrow gap arc welding, manual arc welding, and can also be combined with DC or AC arc welding power supplies to form (DC+AC) or (AC+AC) double-wire, multi-wire high-efficiency arc welding systems.

1. Using IGBT inverter technology to ensure that the welding specifications are highly stable when the grid voltage and arc length change.

2. High efficiency and power factor, thus having significant power saving effects and high grid utilization.

3. The welding current can be preset with the control box.

4. With the control box, 12 sets of welding parameters can be stored.

5. The control box and the host are photoelectrically isolated to avoid damage to the control line and burning of the mainboard.

6. The fan starts when welding and stops after 10 minutes of welding, which can reduce noise, save electricity and increase the life of the fan.

7. No magnetic blow: Due to the use of AC square wave output, the arc is stable, the weld is beautiful, and it is not easy to produce welding defects.

applications

1. Steel Structure Fabrication – Used for welding box beams, and steel columns in industrial buildings and bridges.

2. Shipbuilding & Offshore Engineering – Ensures stable, deep-penetration welding for large steel plates and marine structures.

3. Pressure Vessels & Boilers – Ideal for welding thick-walled tanks and high-strength pressure components.

4. Wind Power & Energy Equipment – Applied in tower, pipe, and energy equipment welding with high precision.

5. Heavy Machinery Manufacturing – Improves efficiency in welding frames, cranes, and construction equipment.

6. Railway & Transportation Industry – Suitable for long-seam welding of steel bridges and vehicle structures.

7. Automatic Welding Lines – Easily integrated into automated beam and column production systems.