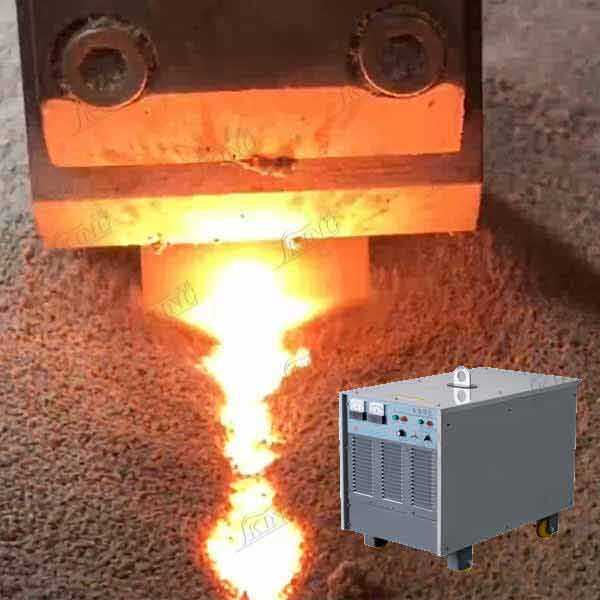

new esw welding equipment

The new ESW (Electroslag Welding) equipment represents a significant advancement in welding technology, offering unprecedented precision and efficiency for heavy-duty industrial applications. This state-of-the-art system combines robust mechanical design with intelligent digital controls to deliver superior weld quality in vertical joints of thick materials. The equipment features an advanced power source capable of delivering up to 1000 amps consistently, ensuring deep penetration and complete fusion. The automated feed system maintains optimal flux and wire delivery rates, while the integrated cooling system prevents overheating during extended operations. The equipment's modular design accommodates plates ranging from 25mm to 300mm in thickness, making it versatile for various industrial applications. The digital control interface provides real-time monitoring of critical parameters including current, voltage, and travel speed, allowing operators to maintain precise control over the welding process. Safety features include emergency shutdown systems and thermal protection circuits. The equipment's robust construction ensures reliability in demanding industrial environments, while its innovative design minimizes setup time and simplifies maintenance procedures.