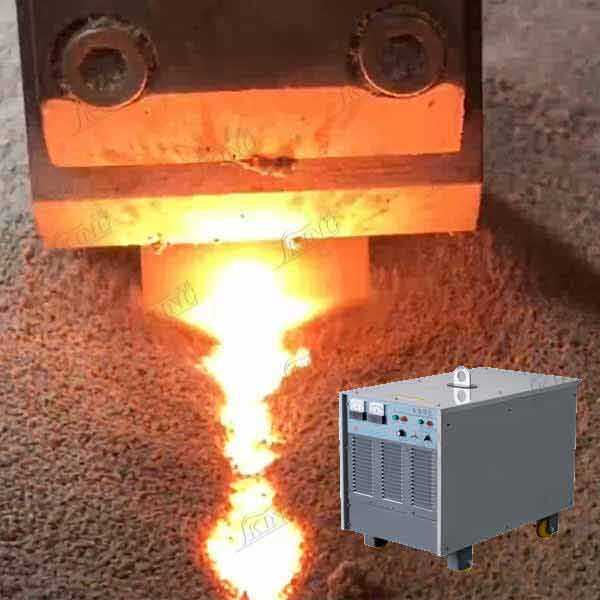

esw welding machine

The Electroslag Welding (ESW) machine represents a groundbreaking advancement in welding technology, specifically designed for heavy-duty industrial applications. This sophisticated welding system excels in joining thick metal plates, typically ranging from 1 to 12 inches in thickness, through a unique process that utilizes electrical resistance heating and molten slag. The machine operates by maintaining a molten slag pool between the workpieces, which is heated by electrical current passing through it. This innovative approach creates a continuous welding process that produces high-quality, deep-penetration welds in a single pass. The ESW machine features advanced controls for maintaining optimal welding parameters, including current regulation, voltage monitoring, and feed rate adjustment systems. Its robust construction includes a water-cooling system to prevent overheating during extended operations, while the automated guide mechanisms ensure precise alignment throughout the welding process. The machine is particularly valuable in industries such as shipbuilding, structural steel fabrication, and heavy equipment manufacturing, where it significantly reduces welding time and material costs compared to traditional methods. Modern ESW machines incorporate digital interfaces for precise parameter control and real-time monitoring capabilities, enabling operators to achieve consistent, high-quality results while maintaining efficiency in production environments.