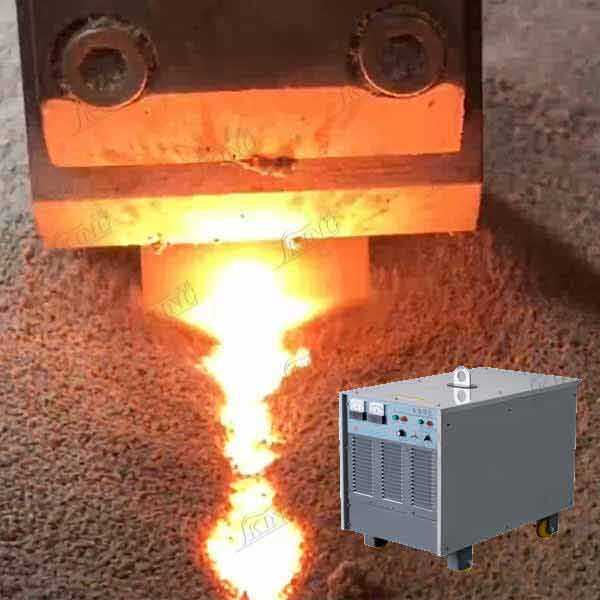

esw welding process

Electroslag welding (ESW) is an advanced welding process that revolutionizes the joining of thick metal plates in a single pass. This highly efficient method employs a molten slag bath maintained at temperatures exceeding 1800°C, which acts as both a heating medium and protective environment for the weld. During the ESW process, a consumable guide tube feeds filler metal into the joint while electrical current passes through the conductive slag, generating the heat necessary for welding. The process is particularly notable for its ability to weld materials ranging from 1 to 12 inches in thickness, making it invaluable for heavy industrial applications. The entire operation occurs within a copper shoe setup that contains the molten metal and slag, ensuring precise control over the weld geometry. ESW demonstrates remarkable efficiency in vertical welding positions, where it excels at joining thick plates in a single pass, significantly reducing operation time compared to traditional multi-pass welding methods. The process finds extensive application in shipbuilding, heavy equipment manufacturing, structural steel construction, and the fabrication of pressure vessels, where thick-section welding is a common requirement. The automated nature of ESW ensures consistent weld quality and minimizes operator fatigue, while its high deposition rate makes it economically advantageous for large-scale industrial projects.