esw welding machine suppliers

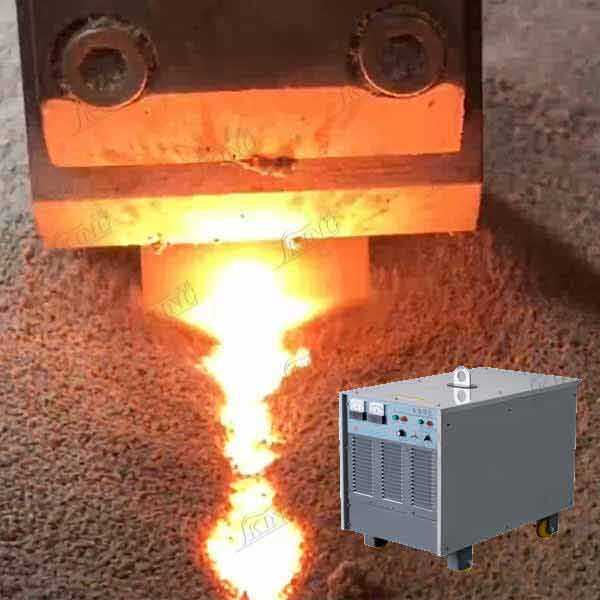

ESW welding machine suppliers provide essential equipment for electroslag welding, a highly efficient process used in heavy industrial applications. These suppliers offer comprehensive solutions that include advanced power sources, wire feeding systems, and control units designed for optimal welding performance. The machines are engineered to handle thick plate sections ranging from 1 to 12 inches, making them ideal for heavy fabrication industries. Modern ESW equipment features sophisticated digital controls for precise parameter adjustment, automated monitoring systems for quality assurance, and integrated cooling systems for continuous operation. These machines excel in vertical welding applications, particularly in shipbuilding, pressure vessel manufacturing, and heavy construction sectors. Suppliers typically provide complete systems with flux feeding mechanisms, oscillation controls, and specialized monitoring equipment to ensure consistent weld quality. The technology incorporates advanced features such as real-time weld pool monitoring, automated slag depth control, and precise electrode positioning systems. Many suppliers also offer customization options to meet specific industrial requirements, including various plate thicknesses and material compositions.