اللحام العمودي: تقنيات وأفضل الممارسات لضمان سلامة الهيكل

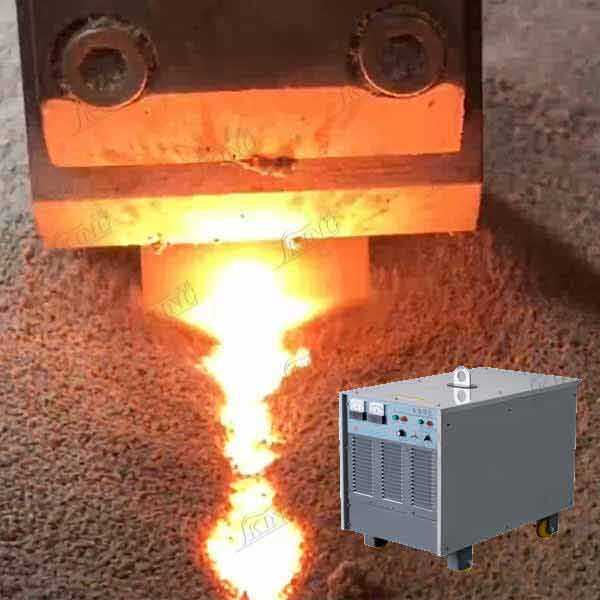

اكتشف الدور الأساسي للحام الأعمدة في البناء الهيكلي، واستكشف توزيع الحمل، والاستقرار، والتقنيات الشائعة للحام، وإرشادات السلامة. تعلم كيف يضمن لك اللحام الكهربائي (MIG)، واللحام بالقوس الكهربائي (TIG)، واللحام العصوي (Stick Welding) لحامًا قويًا وموثوقًا مع فهم أهمية اختيار الفولاذ ومعالجات ما قبل اللحام.

عرض المزيد