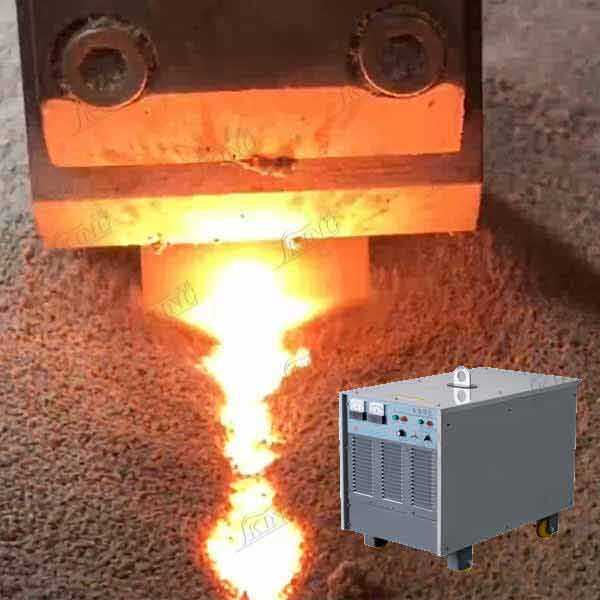

esw welding for steel

Electroslag welding (ESW) for steel represents a highly efficient and specialized welding process designed specifically for joining thick steel plates in a vertical position. This advanced welding technique utilizes electrical resistance heating and a molten slag bath to create high-quality, deep-penetration welds in a single pass. The process begins with the establishment of a molten slag pool contained by water-cooled copper shoes on either side of the joint. As the welding progresses, the heat generated by the electrical current passing through the conductive slag melts both the filler metal and the base material edges. The molten metal then solidifies beneath the slag pool, creating a continuous, high-integrity weld. ESW is particularly valuable in industries requiring thick steel plate joining, such as shipbuilding, heavy machinery manufacturing, and structural steel construction. The process can efficiently weld steel plates ranging from 1 to 12 inches in thickness, making it an ideal choice for heavy industrial applications. Modern ESW systems incorporate advanced monitoring and control systems to ensure consistent weld quality and optimal performance throughout the welding process.