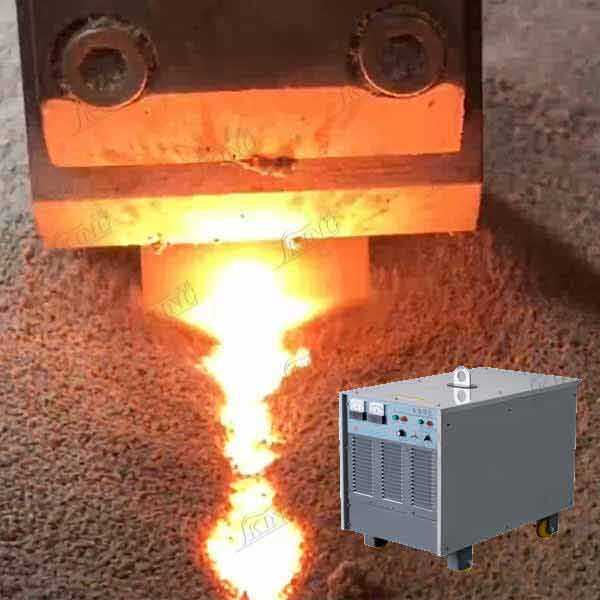

smart esw systems

Smart ESW (Electronic Switch) systems represent a groundbreaking advancement in modern automation and control technology. These sophisticated systems integrate advanced microprocessors, intelligent sensors, and network connectivity capabilities to deliver unprecedented control over electrical systems. The core functionality includes real-time monitoring, automated response mechanisms, and remote operation capabilities. The system architecture comprises three main components: the central control unit, distributed sensor networks, and intelligent switching modules. Each component works in harmony to provide comprehensive system management, energy optimization, and enhanced safety features. The technology utilizes advanced algorithms to analyze usage patterns, predict potential issues, and automatically adjust settings for optimal performance. In practical applications, smart ESW systems are deployed across various sectors, including industrial automation, smart buildings, and energy management systems. These systems excel in load balancing, power distribution, and emergency response scenarios. The integration capabilities allow seamless connection with existing building management systems and IoT platforms, enabling comprehensive facility control. With built-in diagnostic capabilities, the system continuously monitors its performance and components, providing predictive maintenance alerts and reducing downtime. The user interface is designed for intuitive operation, featuring both local control panels and remote access through secure web portals or mobile applications. This combination of advanced technology and user-friendly operation makes smart ESW systems an essential component in modern electrical infrastructure.