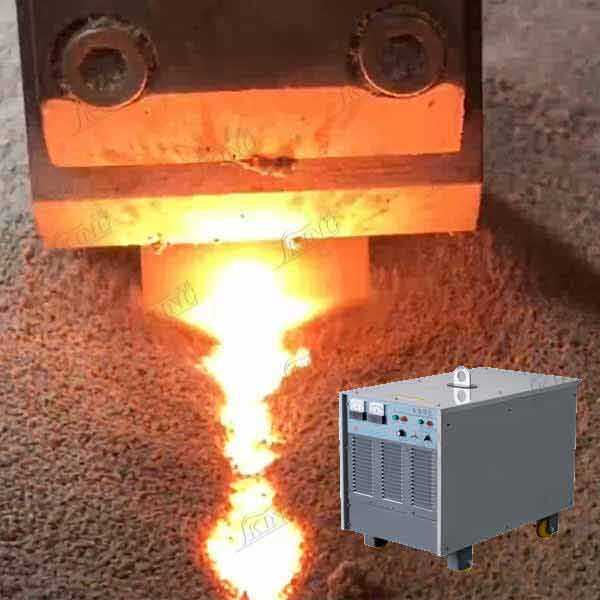

esw welding for large projects

Electroslag welding (ESW) stands as a revolutionary technique for large-scale industrial projects, offering unparalleled efficiency in joining thick metal sections. This advanced welding process utilizes electrical resistance heating and molten slag to create seamless, high-quality welds in vertical positions. The process begins with a copper shoe on either side of the joint, creating a cavity that's filled with molten metal and flux. As the welding progresses, the heat generated by the electrical current passing through the conductive slag bath melts the base metal and filler wire, forming a strong, continuous weld. ESW is particularly valuable for projects requiring welds on materials ranging from 1 to 12 inches in thickness, making it ideal for heavy industrial applications. The technology incorporates sophisticated monitoring systems that ensure consistent weld quality throughout the process, while automated controls maintain optimal welding parameters. This method excels in applications such as shipbuilding, bridge construction, and heavy equipment manufacturing, where large metal sections must be joined with maximum efficiency and reliability. The process significantly reduces labor costs and time compared to traditional welding methods, while maintaining exceptional weld integrity and structural strength.