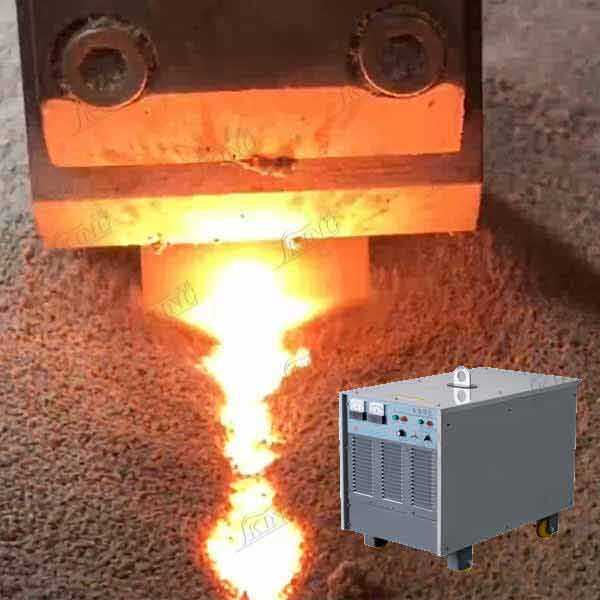

portable esw equipment

Portable ESW (Electro Slag Welding) equipment represents a significant advancement in modern welding technology, offering a compact and mobile solution for high-quality welding operations. This innovative system combines the precision of traditional ESW with unprecedented portability, making it ideal for various industrial applications. The equipment features a sophisticated digital control interface that enables precise parameter adjustment, ensuring optimal welding performance across different material types and thicknesses. The system incorporates advanced cooling mechanisms and automated wire feeding systems, maintaining consistent weld quality while reducing operator fatigue. Its modular design allows for quick setup and dismantling, making it particularly valuable for field operations and remote work sites. The equipment includes integrated safety features such as thermal protection systems and emergency shutdown capabilities, ensuring operator safety without compromising performance. With its ability to handle both thin and thick materials, the portable ESW equipment demonstrates exceptional versatility in applications ranging from structural steel fabrication to heavy equipment manufacturing. The system's smart monitoring capabilities provide real-time feedback on welding parameters, allowing for immediate adjustments and quality control during operation.