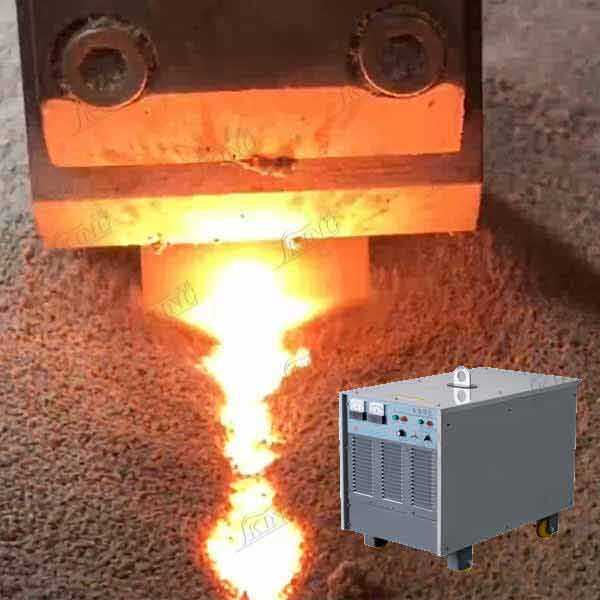

electroslag welding equipment maintenance

Electroslag welding equipment maintenance encompasses a comprehensive system of procedures designed to ensure optimal performance and longevity of this sophisticated welding technology. The maintenance protocol focuses on three critical areas: the power source system, cooling mechanisms, and slag management components. Regular inspection and maintenance of the power supply ensure stable current delivery, while the cooling system requires periodic cleaning and coolant replacement to maintain optimal operating temperatures. The slag bath monitoring system, crucial for weld quality, demands regular calibration and cleaning of sensors. Maintenance technicians must pay particular attention to the electrode guide mechanisms, ensuring smooth wire feed and precise positioning. The copper shoes, which contain the molten metal pool, require regular inspection for wear and proper cooling circulation. Additional maintenance tasks include checking electrical connections, lubricating moving parts, and verifying the integrity of water-cooling circuits. This systematic approach to maintenance not only extends equipment life but also guarantees consistent weld quality and reduces costly downtime. The maintenance schedule typically includes daily operational checks, weekly intensive cleaning, monthly comprehensive inspections, and quarterly major service interventions.